Description

AW 26 Alloy Wheel Lathe Productivity and Profit.

Over the past few years we have dedicated ourselves to pursue higher technological levels and strived to provide a number high quality lathe models that will not only provide years of dependable performance but that will meet and exceed the market demand for the years to come.

In addition, we have enhanced and expanded our research and development programme to seek improvements which add value.

The AW 26 hasa unique construction which in turn reduces the foot print required for stability. Currently able to resurface most Oem derived alloy wheels up to 24 ins in diameter.

£19995.00 + Vat

4 position tool turret

MPG hand wheel headstock and oil cooler 3 hp spindle motor

Chip tray / conveyor rim hub mounted system

Touch probe

All castings are made of high tensile meehanite cast iron eliminating internal residual stress. Spindle & gears are constructed from CR-MO alloy steel and precisely ground.

AC main spindle motors.

Inverter controlled spindle drive, in combination with automatic cross feed delivers greater cutting accuracy and efficiency for facing work associated with the cutting of alloy wheels.

Inverter controlled spindle braking.

Automatic lubrication system fitted as standard for extended service life. .

Unique bed construction carefully designed for maximum stability and increased rigidity whist retaining a small foot print.

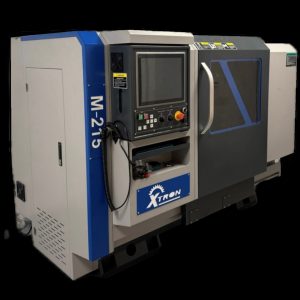

| Model |

M 200 |

|

Operating Controller |

3 HP Spindle Motor |

Quick change Tool Post |

15 ins 3 jaw chuck with soft jaws |

Automatic lubrication system |

Coolant system and pump |

Digitizing probe |

Volateg 220V/1PH/50HZ |

|

|

|

|

|

|

|

|

|

Foot print dimensions:

The actual machine dimensional sizes are (L*W*H): 1120*850*1730, we recommend that an 800mm access clearance is maintained around the machine to the rear, right and left hand if fitted in a workshop.

If fitted in a van the machine can be fitted closely to either side or rear of the panelling or bulk head.

Machine/Packing size (L*W*H): 1120*850*1730/1260*1010*2140mm

Max. wheel cutting size: 28’’

Machine floor space: 0.95m²

X/Z axis position accuracy: 0.001mm

Chuck & claw: 13’’ chuck with 3 extended claw

Range of spindle speed: 10-850rpm