Description

Xtron M210v Verticle Alloy Wheel Lathe

With over 12 years of experience in supplying and manufacturing alloy wheel lathes, we understand what makes a truly exceptional machine.

Our continuous pursuit of quality has driven us to design and produce high-performance lathe models that not only deliver years of reliable service, but also meet and exceed market demands well into the future.

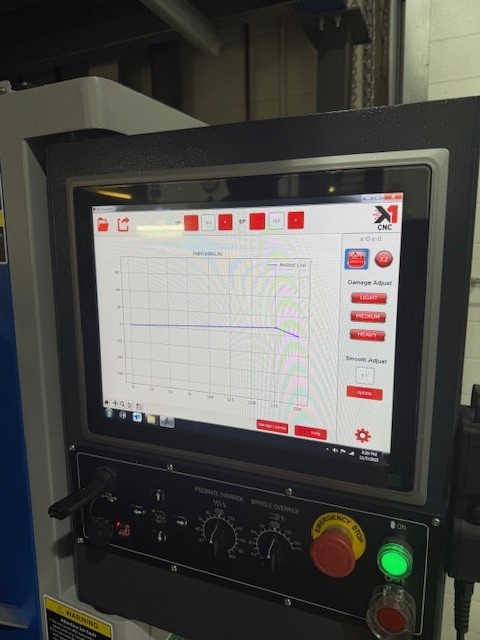

Dedication to in house research and development, has focused on innovation and value enhancement, our unique software and the ability to offer customised solutions ensure our lathes stay at the forefront of technology and efficiency.

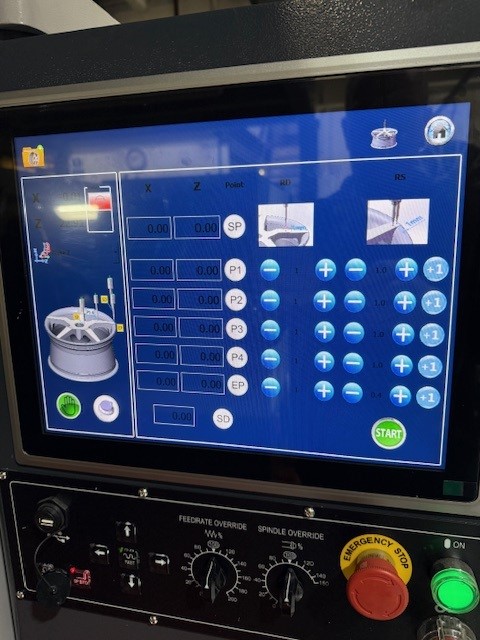

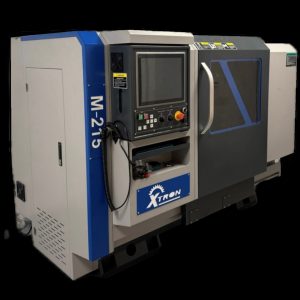

The Xtron M210V Vertical Alloy Wheel Lathe embodies this commitment, featuring touch-screen operation, precision-engineered linear guide rails, and an ergonomic design optimised for technician comfort, the M210V delivers superior usability and performance.

Its vertical construction introduces a lower center of gravity for enhanced stability and a smaller footprint, making it ideal for modern workshops with limited space.

The M210V can remanufacture most OEM-derived alloy wheels up to 24 inches in diameter (tyre off) or 22 inches (tyre on)

The M210 Verticle can be used in a workshop or due to its weight of just 580 kg and single phase 240v power supply can be used in a mobile process

£29,995 + Vat

to view a short video follow this link : https://www.youtube.com/shorts/gPnVBHObVUo